3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Isn’t this exactly what Pressure Advance does?

To my understanding, pressure advance only compensates for non-linearities in the extrusion process. These non-linearities, if not taken into account would thin out the path at the beginning (missing pressure) and lead to an excess of material at the end (excess pressure buildup).

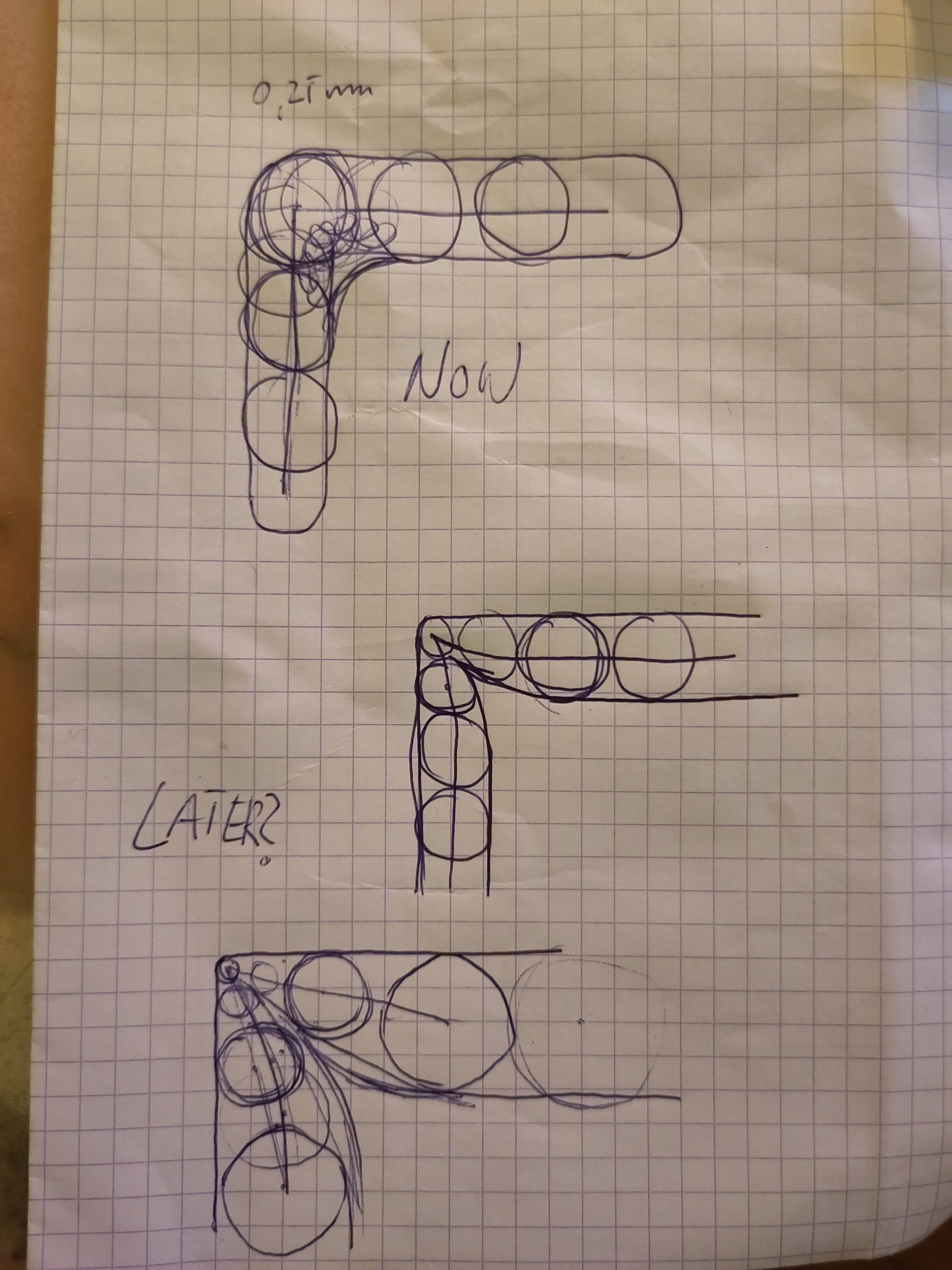

With perfect compensation of these non-linearities but no changes to the target line-width and path, the minimum achievable outer radius is equal to that of the extrusion width. I'm wondering if that minimum radius could not be reduced by progressively reducing the target extrusion width the closer you get to the corner. On top of that you would need to adjust the path towards the outside in order to keep the outer wall straight.

Edit: to my understanding, a classical corner will also result in a buildup of material inside, this can be explained by the nozzle orifice dwelling longer on the inside of the corner. This excess moves to the inside, creating a round corner on the inside as well.

My proposal would also combat this inner excess, thus giving overall sharper corners.

Exactly. And the PA tuning that Ellis has is great for tweaking it.

Maybe my sketch doesn't make it clear. I mean to intentionally make the extrusion narrower and make the print path go outwards to compensate for the narrower extrusion.

Pressure Advance does it. It reduces the extrusion at corners, accounts for coast speed, etc.

The actual extrusion or the extruder input? Of course it will also reduce the extrusion if badly tuned, I guess that's not the idea though. PA is also needed for straight lines with variable speed. It does help with corners but would need additional path corrections.

As shown in my sketches below: