3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

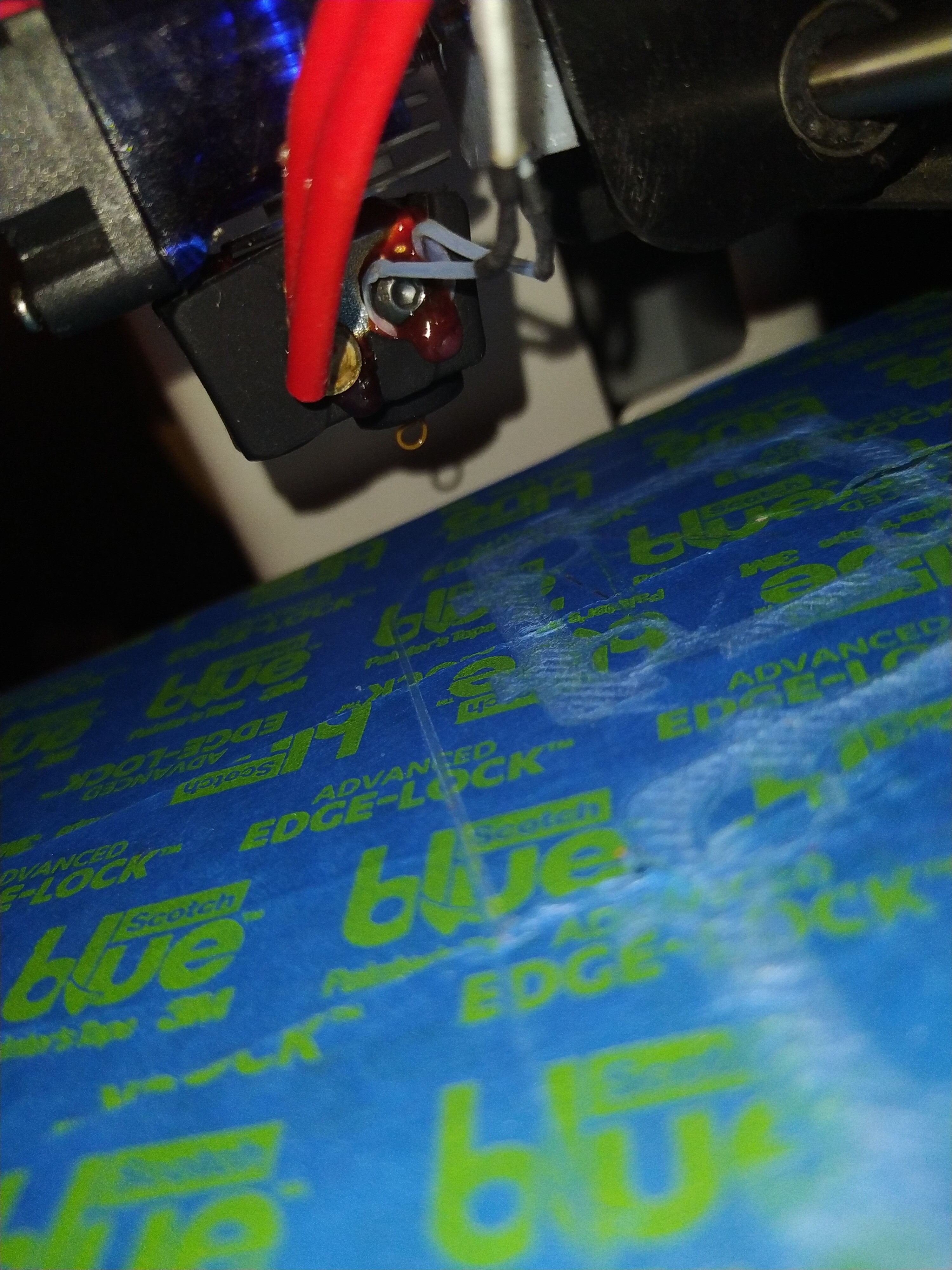

In my experience the hole that the thermistor goes into isn’t in the path of the filament. So probably what’s happening is either the nozzle or the tube that screws into the other side of the heater block is loose, allowing melted plastic to escape through a place other than the tip of the nozzle.

After you’ve cleaned it out, what I like to do before running filament through again is to turn the hot end on, let it come up to temp, then tighten the nozzle a bit more. The joint expands when heated so even if you’ve got it right at room temp it can still need tightening at the working temperature.

This is definitely the right answer, as I just had to deal with this after a nozzle change.